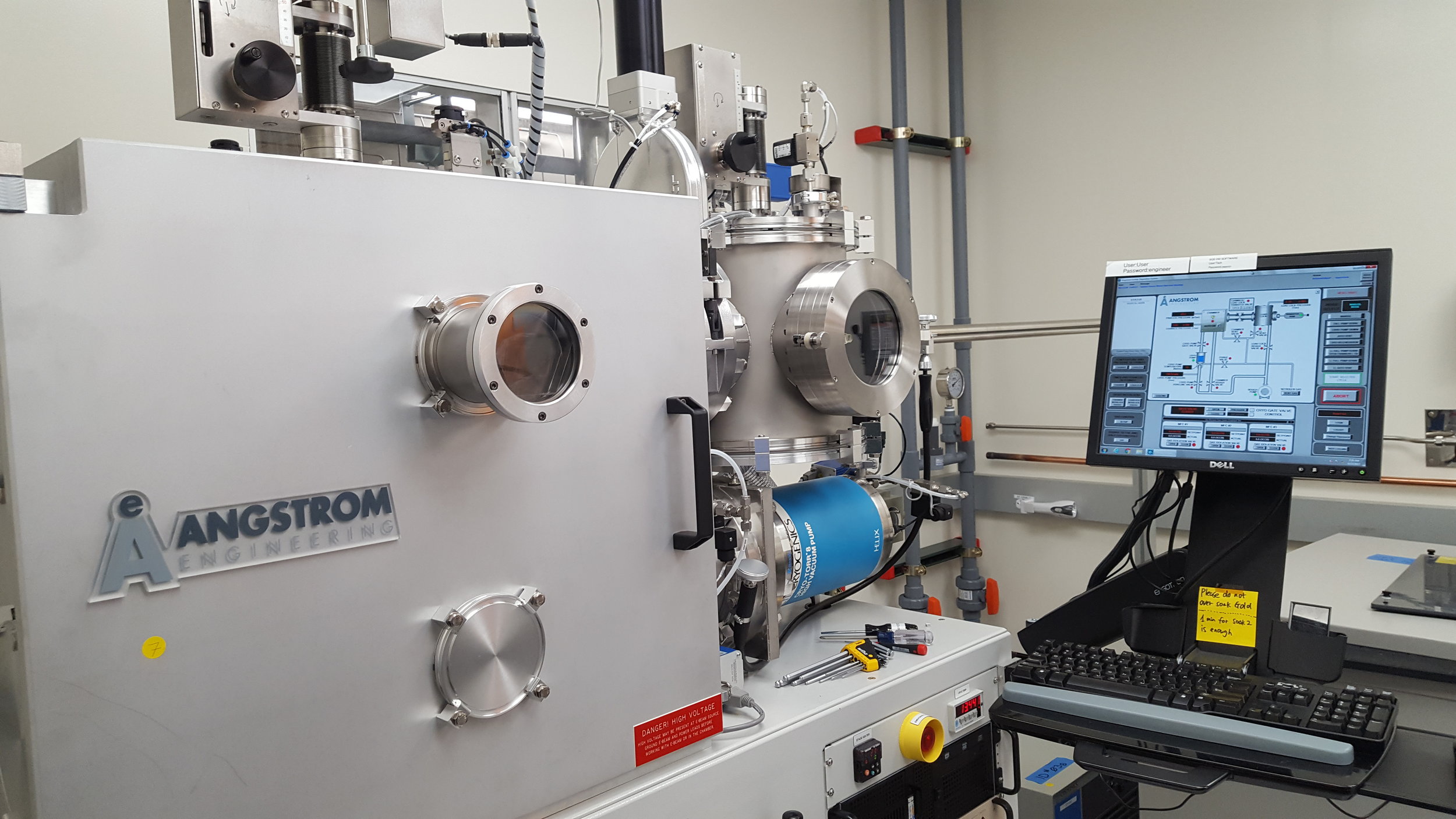

ANGSTROM EVOVAC DEPOSITION SYSTEM

+ SHARED LABS HOME

+ EXTERNAL USER PROGRAM

+ CNI LABS NEWSLETTER

+ BADGER

+ CLEAN ROOM

- CLEAN ROOM HOME

- CLEAN ROOM ACCESS PROTOCOL

- EQUIPMENT TRAINING

- PROCESS & FABRICATION

- EQUIPMENT LIST

- EQUIPMENT RATES & SUPERUSERS

- EQUIPMENT STATUS

- SAFETY

- GROUP RESEARCH

- RELATED LINKS

+ ELECTRON MICROSCOPY

- EM LAB HOME

- SERVICE REQUEST FORM

- EM LAB ACCESS

- TRAINING & CERTIFICATION

- EQUIPMENT LIST & RATES

- FEI TALOS S-TEM

- ZEISS SIGMA VP SEM

- EM IMAGE GALLERY

+ SHARED MATERIAL CHARACTERIZATION LAB

OPERATING INSTRUCTIONS | MORE INFO

GENERAL INFORMATION

Angstrom Engineering’s EvoVac Multi-Process thin film deposition system (AKA: "The Classic Angstrom") allows sample coating using a variety of deposition techniques within the same machine.

Available materials are:

E-Beam (Au, Pd, AuPd, Pt, Ti, Ag, Cr, Co, Sc, Ni, Ru)*

Thermal (Al)

Sputter (Ni, W, Al, Cu, Ti, TaO5, Nb, Cr)

To make a materials request for the Angstrom EvoVac, please use this form:

*Pd,Co, and Pt are mostly available in the UHVAC Angstrom evaporator. Other materials can be considered as well.

Au, Ti, and Cr are available in both evaporators.

THERMAL RESISTIVE EVAPORATION

Two resistively heated evaporation sources can deposit simultaneously. Boats containing Al are typically used for thermal evaporation.

ELECTRON BEAM EVAPORATION

A 6 pocket e-beam source with 12cc crucibles provides the capability to evaporate high melting point materials including refractory metals and ceramics. The beam pattern is optimized for each recipe. Typically only 5 sources will be available to allow the use of sputtering without cross contamination of deposition sources.

SPUTTER DEPOSITION

Two 3” circular sputter sources sharing a 600W RF power supply allow the deposition of metal (including magnetic metals) and ceramic materials. Gas ambient sputtering is optional.

DEPOSITION CONTROL

Deposition processes are recipe driven and are software controlled using feedback from quartz rate monitors. Shutters are automatically actuated and sources are thermally conditioned based on recipe inputs which allows for a repeatable process. Substrate heating of up to 400C is available.

SUBSTRATE CAPABILITY AND LOAD LOCK

6.0in x 6.0in or smaller substrate pieces can be mounted in the system. Substrates can be loaded into the a storage rack located within the load lock. In some special cases substrates can be loaded directly into the deposition chamber. A special holder for 6” wafers is available upon request.

CONTACT INFORMATION

Users who have access to the clean room can start shadowing a group member for training on the evaporator. For certification on the evaporator (after training) please sign up by filling out the Evaporator Training/Certification Signup.

For additional information about the Angstrom EvoVac Deposition System, please contact the clean room staff at: cniCR@columbia.edu.