NANOFABRICATION CLEAN ROOM FACILITY

+ EXTERNAL USER PROGRAM

+ CNI LABS NEWSLETTER

+ CNI LABS TEAM

+ BADGER

+ CLEAN ROOM

- CLEAN ROOM ACCESS PROTOCOL

- EQUIPMENT TRAINING

- PROCESS & FABRICATION

- EQUIPMENT LIST

- EQUIPMENT RATES & SUPERUSERS

- EQUIPMENT STATUS

- SAFETY

+ ELECTRON MICROSCOPY

- EM LAB HOME

- SERVICE REQUEST FORM

- EM LAB ACCESS

- TRAINING & CERTIFICATION

- EQUIPMENT LIST & RATES

- ZEISS SIGMA VP SEM

- FEI TALOS S-TEM

- EM IMAGE GALLERY

+ SHARED MATERIAL CHARACTERIZATION LAB

Welcome to the Columbia Nano Initiative Nanofabrication Clean Room page!

The cleanroom is open for all processes 24/7 except the corrosives bay, LPCVD, Cl-RIE, and the PECVD which can be used daily between 7am-9pm only.

Please sign up for the CNI Shared Lab Facilities newsletter in order to receive lab updates and important announcements by clicking here: CNI Shared Lab Facilities Newsletter

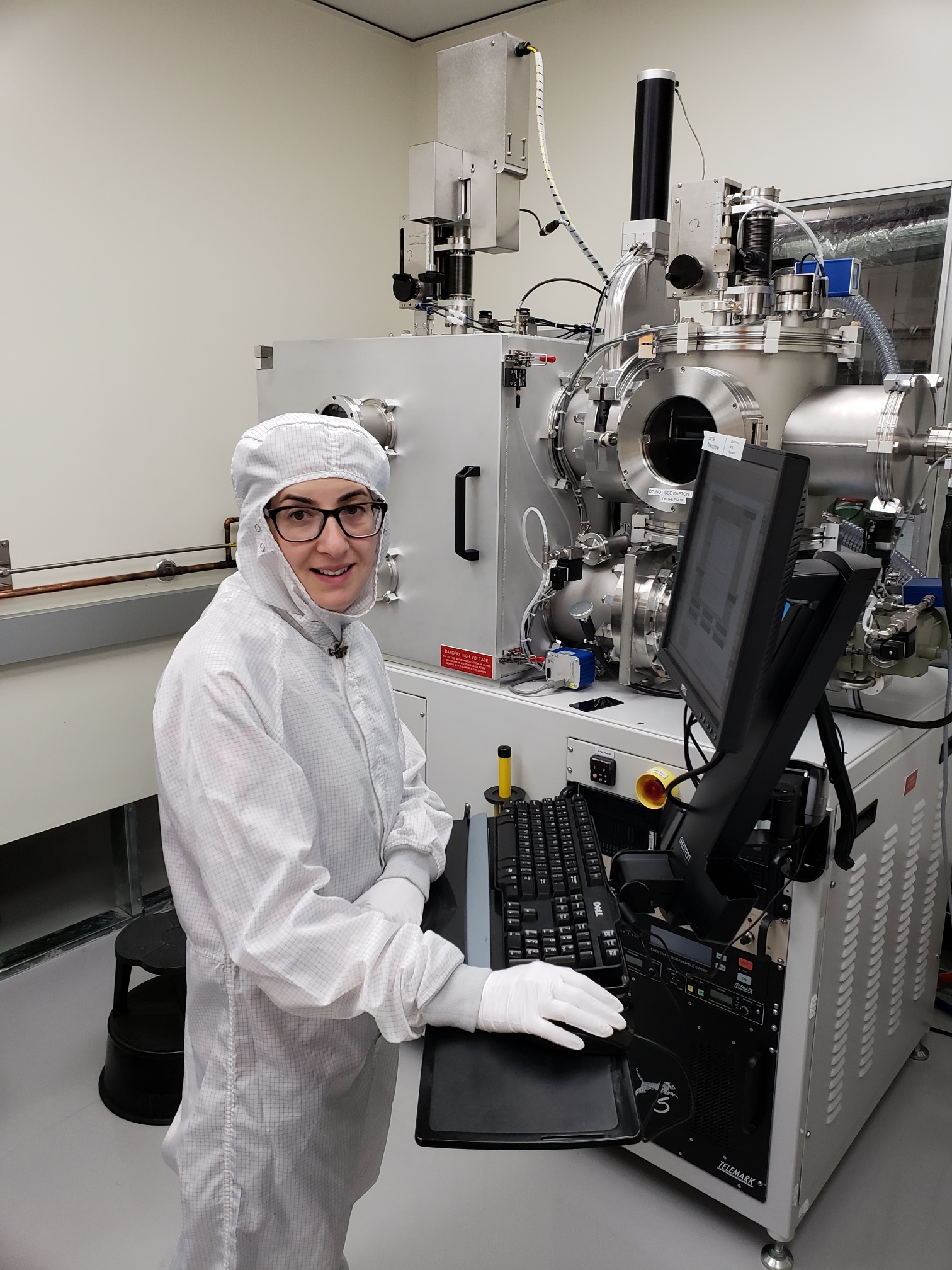

The CNI Nanofabrication Clean Room and EBL is a 5,000-sq. ft. facility in the Morris A. Schapiro Center for Engineering and Physical Science Research (CEPSR) including an electron beam lithography suite in the North West Corner building. It is dedicated to providing the processing tools, instrumentation, technical expertise, and team-teaching environment to support and stimulate collaborative research in nanoscale science and engineering. The facility supports the creation and evaluation of devices and materials with state-of-the-art fabrication and characterization equipment. Applications include nanoelectronic and nanophotonic devices, micro and nano-electromechanical systems (MEMS/NEMS), flexible electronics, bio-electronics, nano-bio interfaces, and more.

This laboratory supports multidisciplinary research across many academic departments and disciplines within Columbia University and welcomes researchers from other academic institutions, government laboratories, and industrial organizations ranging from start-ups to large companies. The research bridges the physical, chemical, biological and medical sciences. The laboratory thus represents a strategic capability for Nanoscale Science and Engineering research at Columbia University.

The recently-renovated and expanded CNI Nanofabrication Clean Room occupies approximately 5,000 square feet of space. It is built to be class 10,000 to class 1,000 but effectively measurements show that it is cleaner. The clean room is divided into 7 separate bays, each dedicated to a set of related fabrication processes:

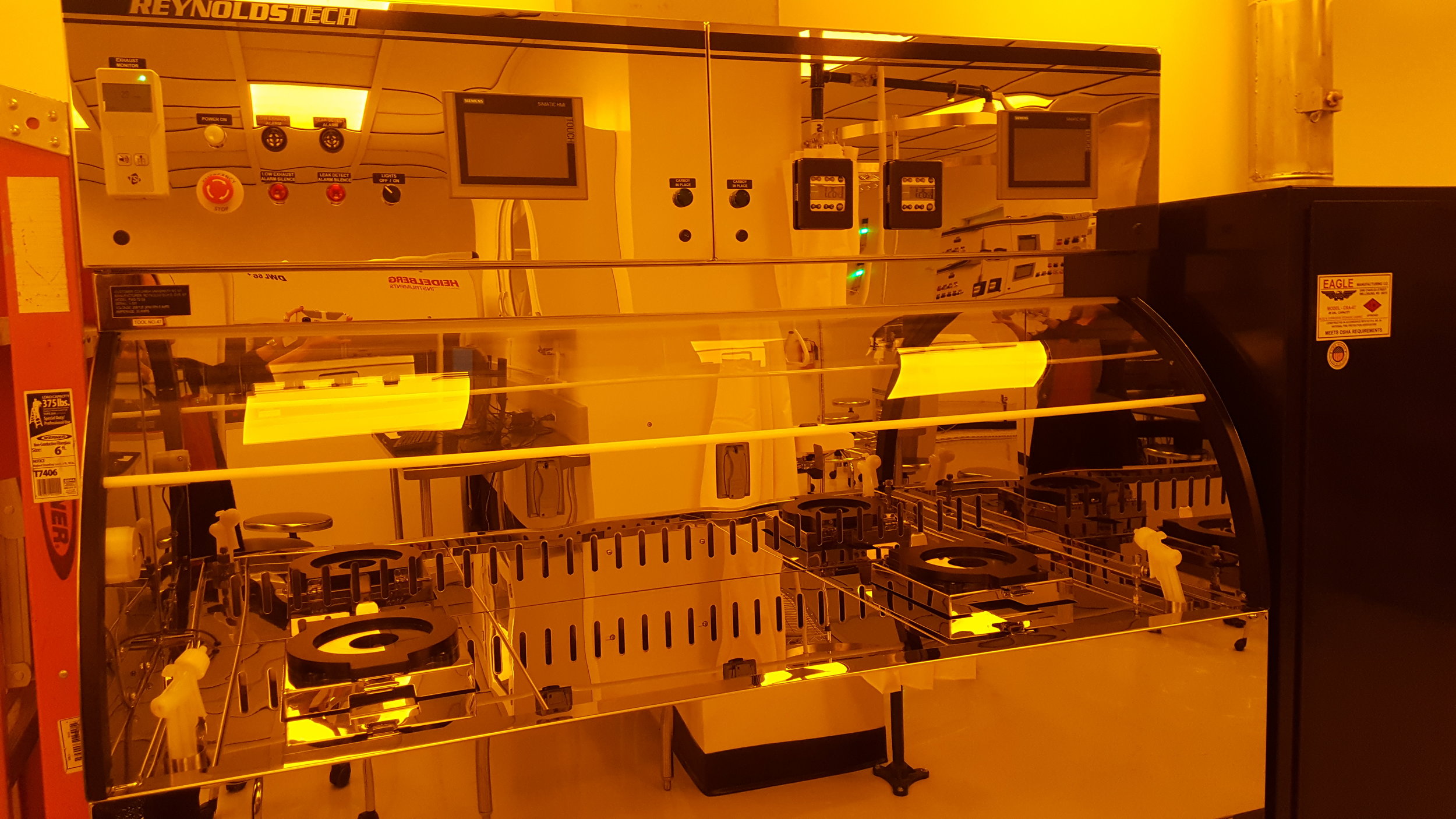

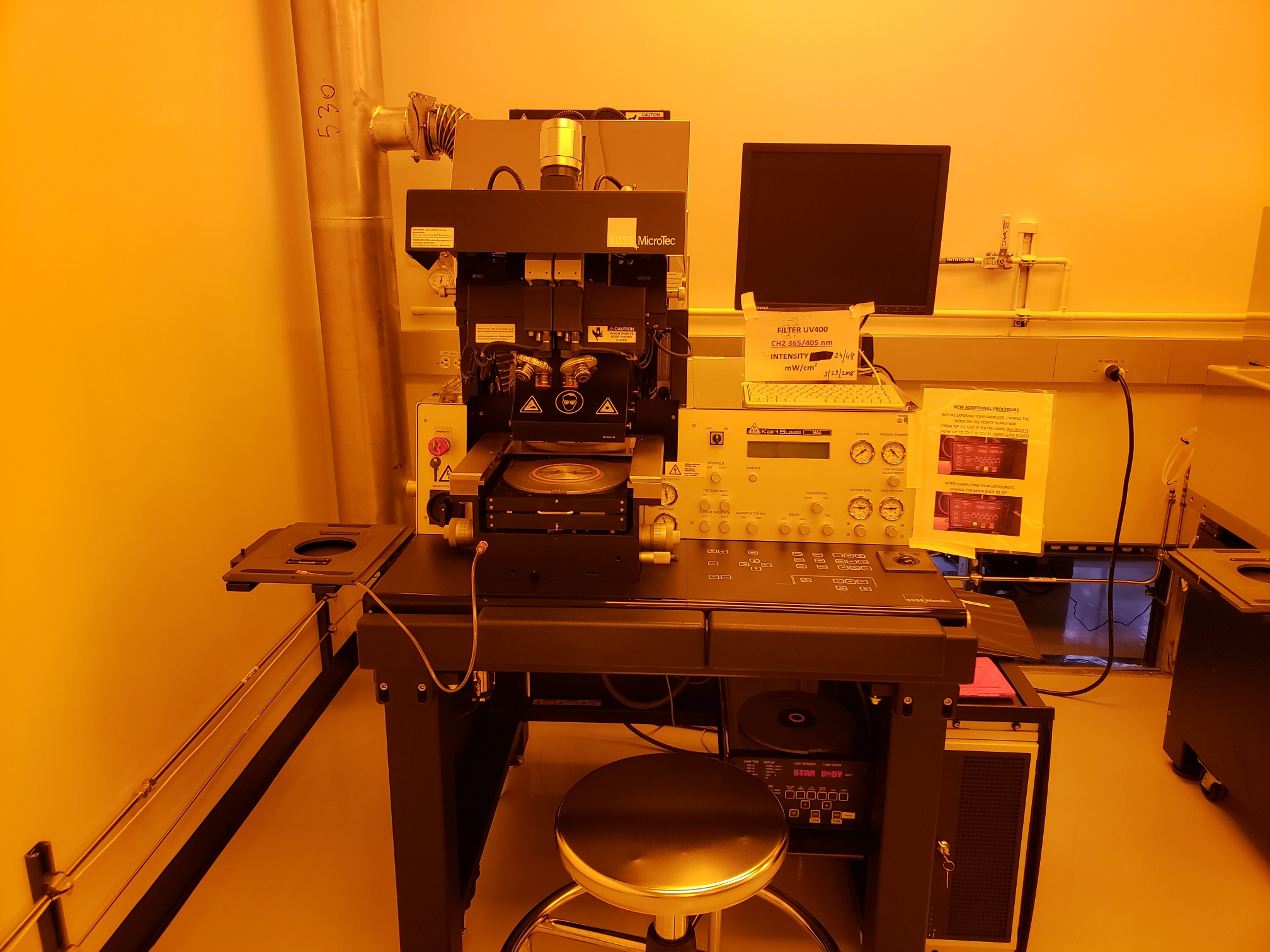

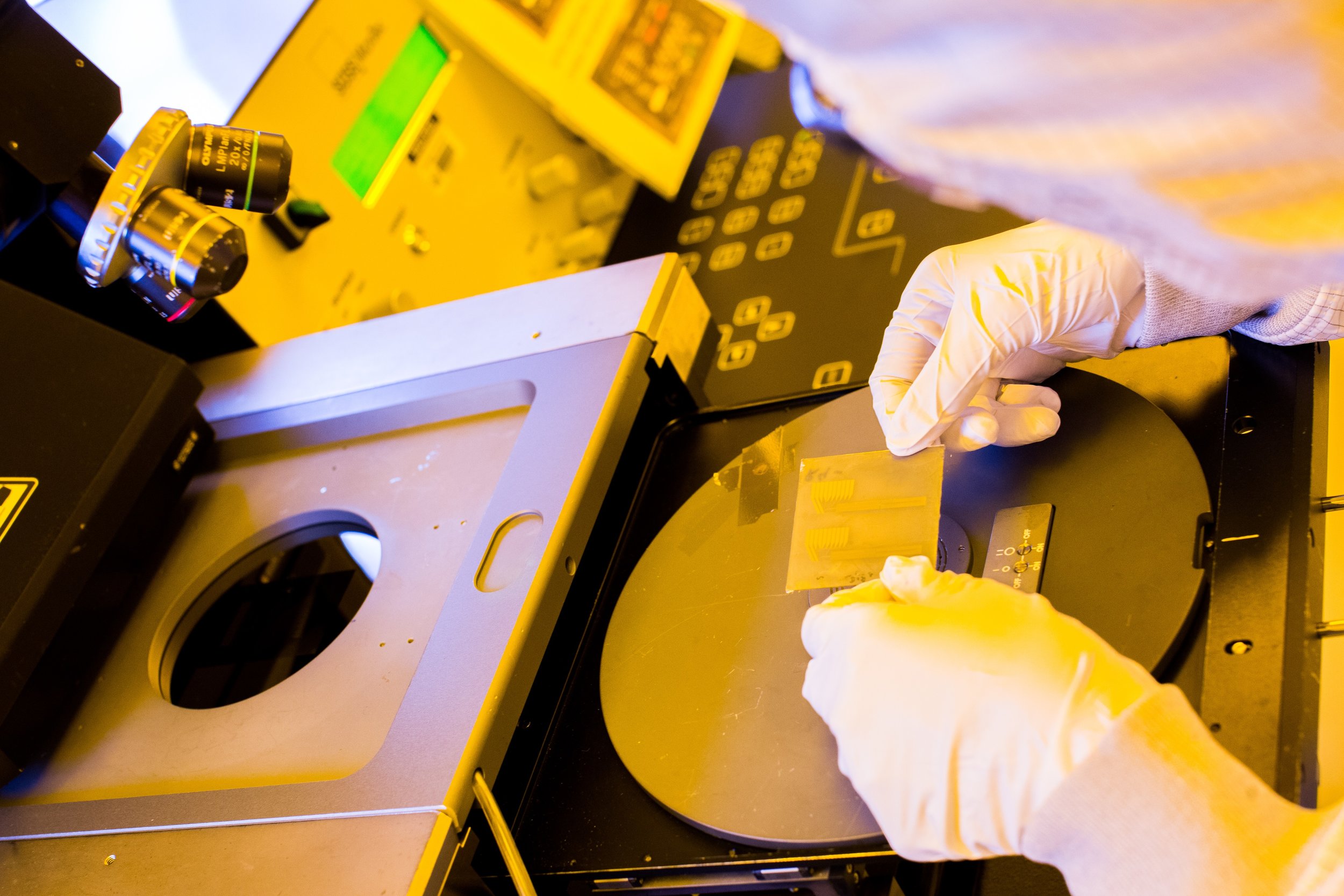

Photolithography bay: includes dedicated fume hoods and photoresist spin-coaters, two mask aligners (one for DUV applications), two mask fabrication systems: a manual laser writing (3µm resolution) and an automatic laser writing system with sub-micron resolution, two plasma ashers (oxygen, argon and forming gas) for substrate preparation and stock photo/e-beam resists (list of supplied resists can be found here: Supplied Resists List).

Wet chemical bay with an automatic RCA-clean bench, spin-rinse dryer for 4" wafers, general acid hood and general base hood for various wet-etch, clean and patterning processes.

Plasma bay with Reactive Ion Etching (RIE) plasma processing based on chlorine and fluorine chemistries, as well as Deep RIE for high aspect ratio and selectivity etching, and PECVD for silicon oxide, silicon nitride, and amorphous silicon deposition.

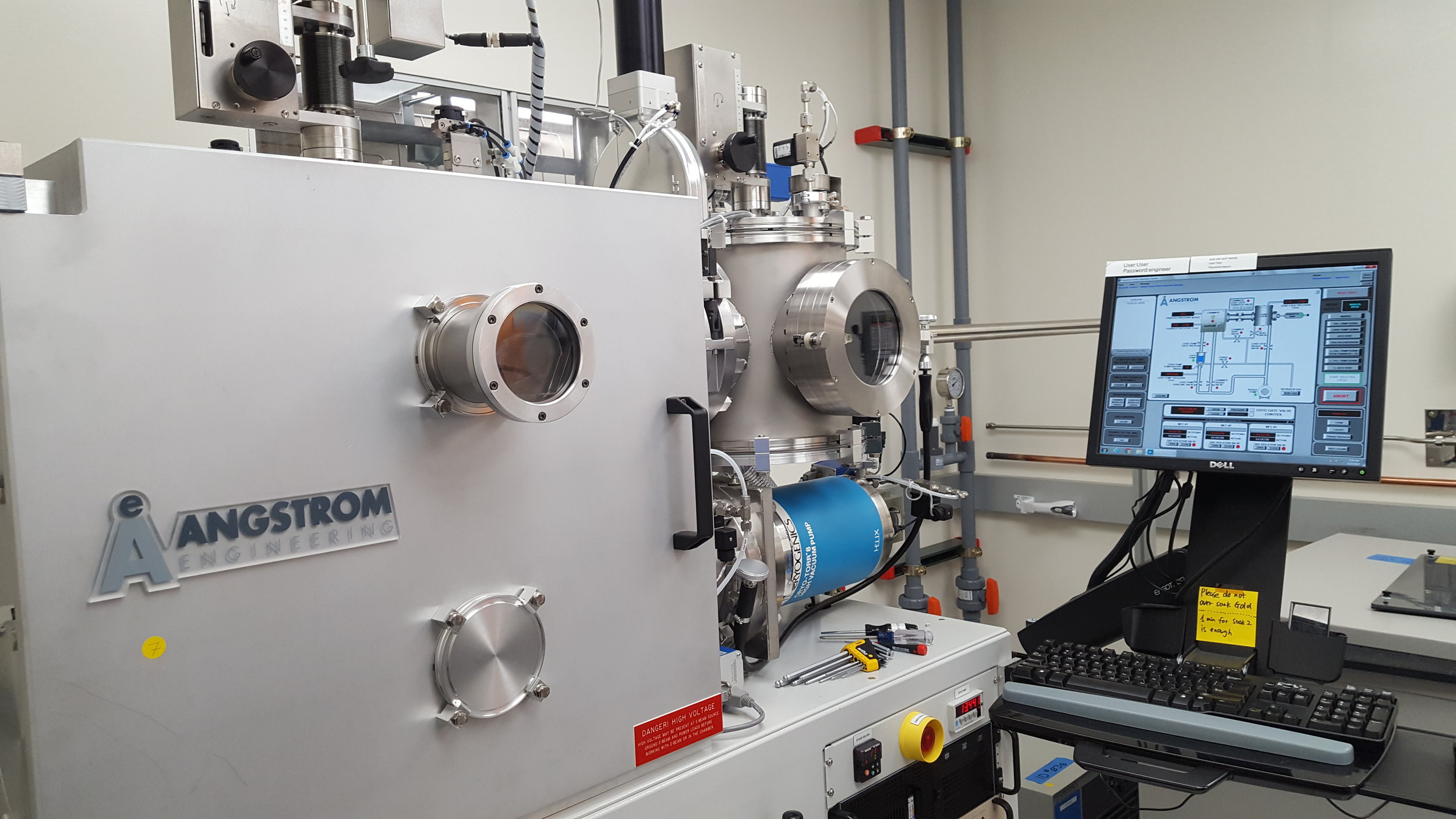

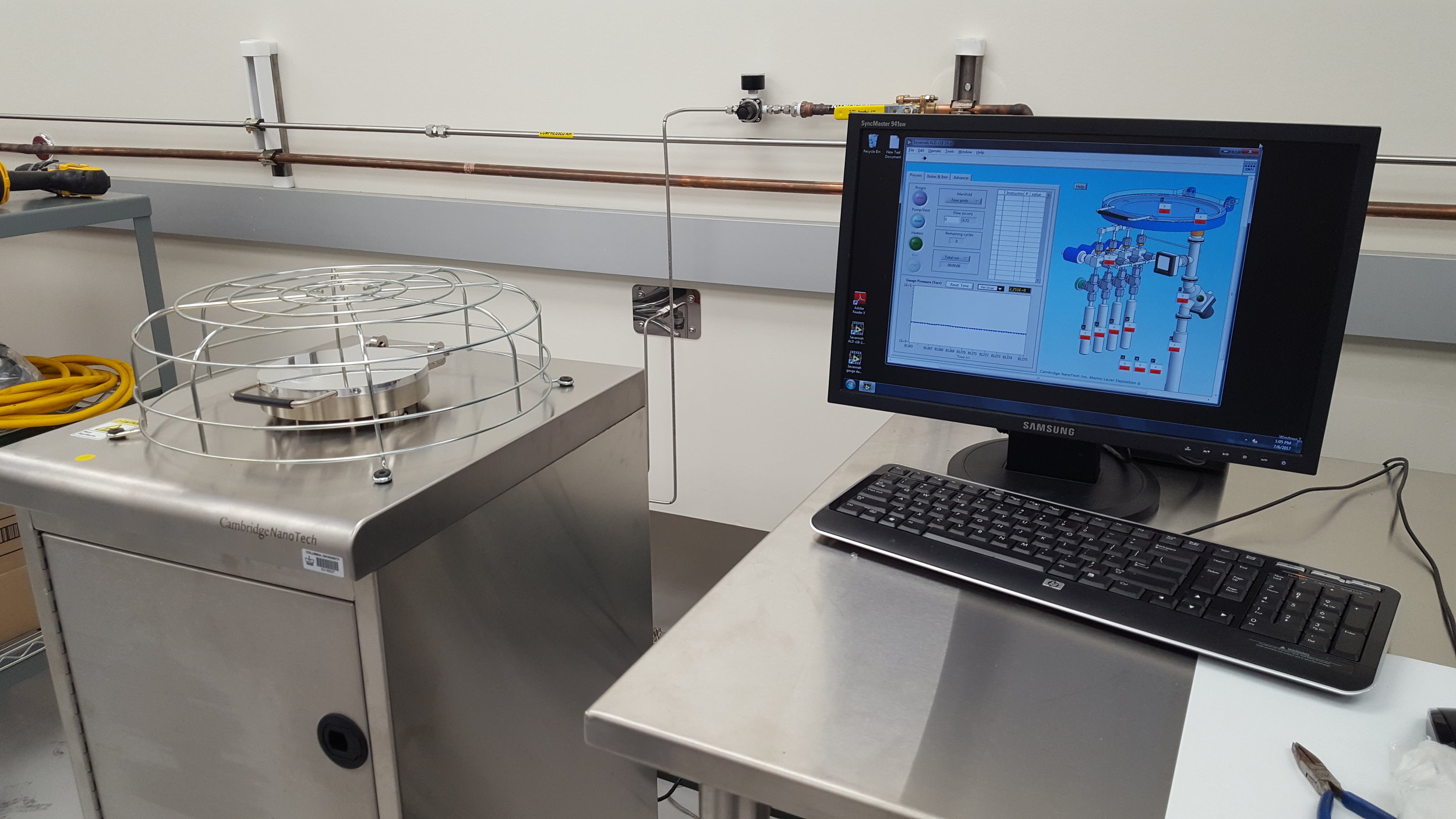

Deposition bay including two sputtering systems (dedicated to metals and dielectrics respectively) that also allow reactive sputtering, an e-beam evaporator, Ultra High Vacuum (UHV) e-beam evaporator, Atomic Layer Deposition (ALD), and a thermal evaporator (the three latter are located in the Plasma bay due to space considerations). The list of evaporation materials supplied by the clean room can be found here: Angstrom EvoVac Deposition System and Angstrom UHV E-BEAM Deposition System. The list of sputtering targets can be found here: AJA Orion 8 Dielectric Sputtering and AJA Orion 3 Metal Sputtering.

Microscopy bay consisting of a FEI Nova NanoSEM 450 (with Nabity Pattern Generation System for e-beam writing), Nikon optical microscopes (with bright/dark field and differential interference contrast), optical profilometry and two Filmetrics thin film characterization systems.

Furnace bay with 4 LPCVD tubes for silicon oxide (thermal, HTO and LTO), silicon nitride, silicon carbide, and thermal annealing capabilities.

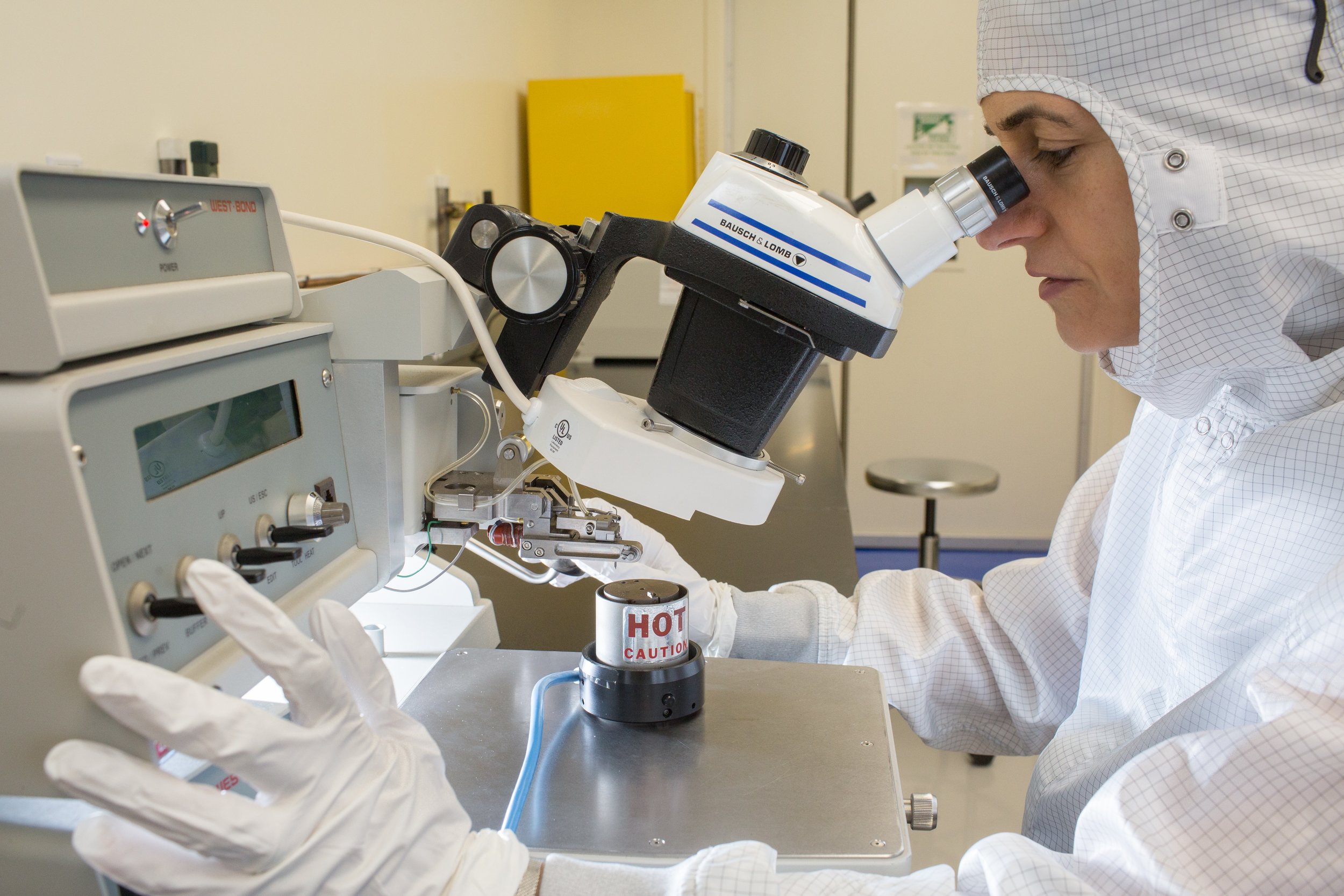

Back-end bay consisting of a Disco dicing saw, G&P chemical mechanical planarization (CMP) system, SCS Parylene coating system, Wire bonders (Al and Au), and a Baltec Critical Point Dryer.

E-beam lithography capability (<10 nm resolution) with Nanobeam nB4, located in the North West Corner building.

Download the clean room brochure here: Clean Room Brochure.

Inventory items (wafers, wafer boxes, tweezers, notebooks, tool belts, etc.) are available to purchase from the clean room office for use in the lab. Prices are subjected to change by the actual cost of the inventory items. List can be found here: Inventory List.

Users of the lab are strongly encouraged to acknowledge CNI labs and MRSEC facilities in their publications using this recommended wording:

Cleanroom and Nanobeam users are strongly encouraged to acknowledge the use of the CNI labs and MRSEC facilities in all publications using this recommended language: “The authors acknowledge the use of facilities and instrumentation supported by NSF through the Columbia University, Columbia Nano Initiative, and the Materials Research Science and Engineering Center DMR-2011738”

James Vichiconti

Cleanroom direcTOR

Office: 1020

Email: jv2534@columbia.edu

Phone: 212 854 9831

*Gallery pictures credit: Timothy Lee

Dr. Youry Borisenkov

Cleanroom Engineer

Office: 1017

email: yb2471@columbia.edu

Phone: 212 851 5688

Mike Maghiar

LABS EQUIPMENT ENGINEER

Office: 1017

email: rmm2263@columbia.edu

Phone: 212 854 3032

tyson allen

research operation assistant

office: 1010

email:

ta2676@columbia.edu

phone: 212 854 1916

dhan cardinal

Cleanroom Engineer

Office: 1017

email: dc3719@columbia.edu

Phone: 212 854 1913