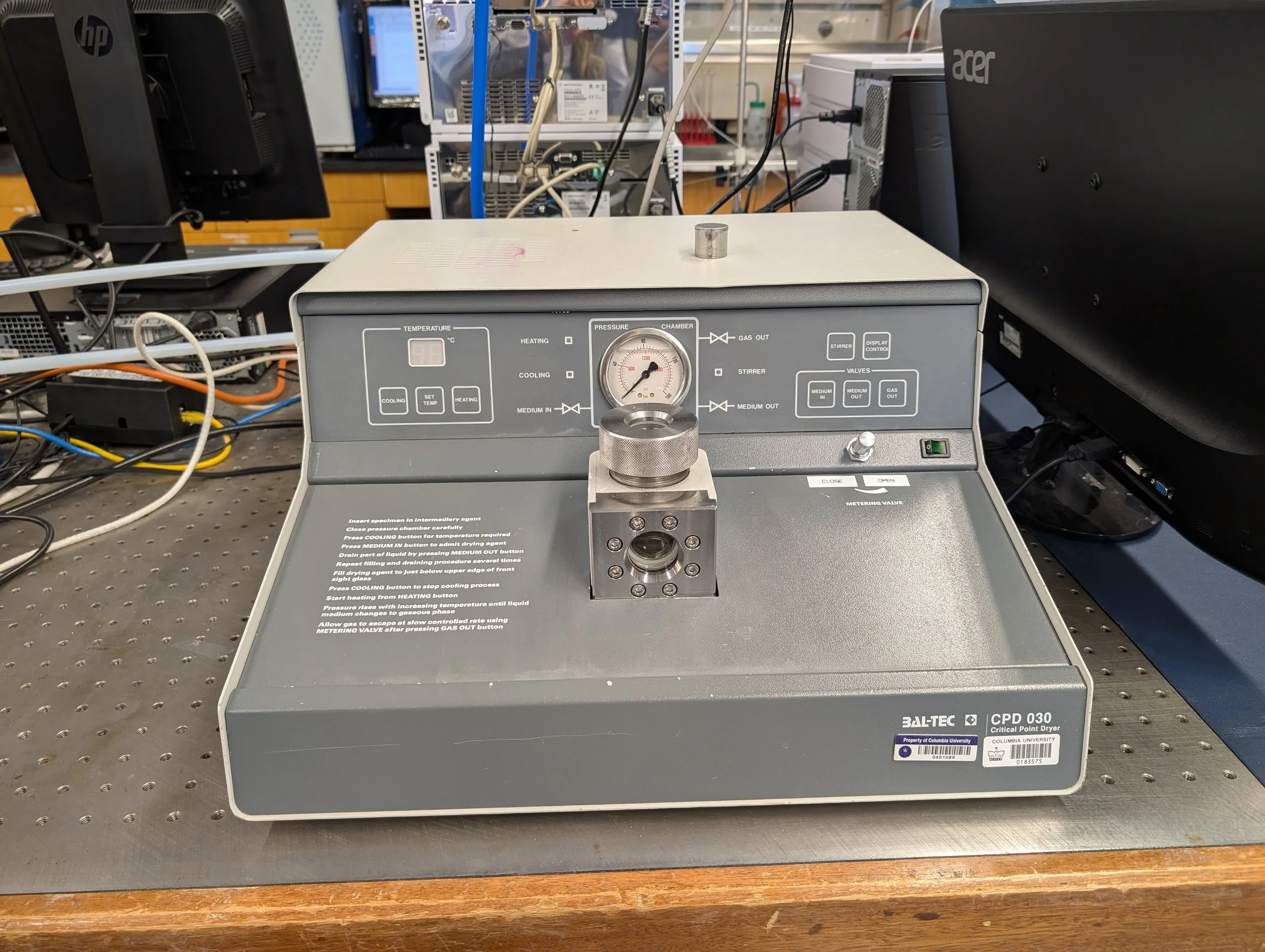

BAL-TEC CRITICAL POINT DRYER

OPERATING INSTRUCTIONS | MANUAL

Location: Havemeyer 544

GENERAL INFORMATION

Critical Point Drying (CPD) is based on a principle of a border in a phase diagram between liquid and gas where liquid and vapor co-exist. The CPD dries the sample by increasing the pressure and temperature of the specimen without crossing a phase boundary. This is possible because once the critical point has been passed, the density of the "liquid" and the density of the "gas" are the same. The critical point for water is 228,5 bar and 374°C. The samples are first treated in a suitable transitional fluid such as CO2 whose critical point of 73.8 bar and 31°C is considerably more advantageous (lower pressure and temperature). CPD can be used for MEMS and NEMS applications to release and dry flexible device structures. Standard release methods can leave particles and cause sticking due to surface tension. The use of supercritical carbon dioxide has been known to alleviate the stiction problem and provide a clean and dry surface due to avoiding surface tension in the supercritical phase of a fluid and CO2 is easy to use because of its phase diagram and where that critical point is.

CONTACT INFORMATION

For additional information about the Bal-Tec Critical Point Dryer, please contact Dr. Amir Zangiabadi or Dr. Luca Telesca.