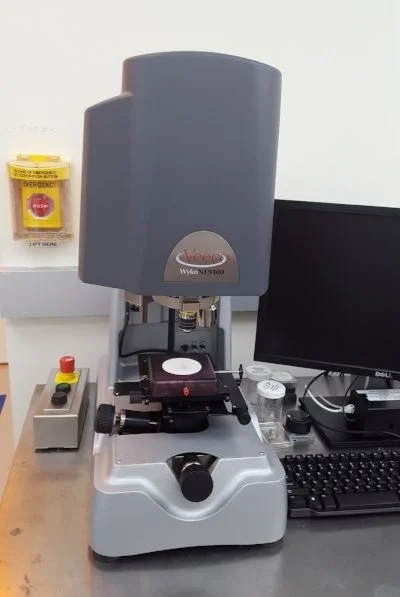

WYKO NT9100 OPTICAL PROFILER

OPERATING INSTRUCTIONS | MORE INFO

GENERAL INFORMATION

The Wyko NT9100 Optical Profile employs coherence scanning interferometry, also known as white-light interferometry, white-light confocal, or vertical scanning interferometry to produce high quality three-dimensional surface maps of the substrate with sub-nanometer vertical resolution. Surface roughness measurements are available as well as 3D surface profiling.

Potential applications: solar cells, MEMS, thick films, optics, ceramics, and advanced materials research.

SPECIFICATIONS

Measurement Capability: Non-contact, three-dimensional, topography and film thickness

Objectives: 10X and 50X

Vertical Resolution <0.1nm

RMS Repeatability 0.05nm

Lateral Spatial Sampling 0.1 to 13.2μm